Stenoflex 400 protect all

- For thermal power plants, Hydroelectric power plants, nuclear power plants.

- For enterprises of chemical, oil-producing, and oil-refining industries.

- Thermal insulation of pipelines in buildings and structures for industrial and civil purposes.

- Insulation of heating networks.

- Insulation of industrial pipelines of all types.

Advantages

- Creates a «thermos» effect.

- High class of fire safety.

- Excellent weather resistance.

- It has an adhesive layer.

- It is resistant to UV radiation.

- It is characterized by low dirt retention/

Go to cart

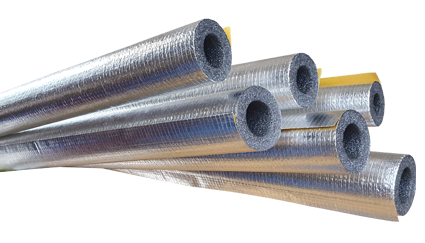

STENOFLEX 400 PROTECT ALL is a professional pipe insulation, characterized by increased strength and reliability. This is achieved by using a particularly strong foil.

Thermal insulation cylinders STENOFLEX 400 PROTECT ALL from «Polifas», this is a great replacement for the well-known cashiered cylinders of the ROCKWOOL 100, ROCKWOOL 150 and TECHNO 80 , TECHNO 120, from TechnoNICOL. Thermoplex-T, XOTPIPE OUTSIDE 100, Foampipe SP ALU.

Purpose and scope of use

It is used as thermal insulation of pipelines in buildings and structures for industrial and civil purposes, for insulation of heating networks, industrial pipelines of all types, with a surface temperature of up to + 90 C, including those located in the open air and exposed to atmospheric influences.

When used correctly, the foil creates an effect of a thermos, reflecting infrared radiation back to the heat carrier. In the case of a pipe made of polyethylene foam, the foil also allows you to achieve a high class of fire safety and excellent weather resistance.

Thermal insulation STENOFLEX 400 PROTECT ALL, among other advantages, has the most neat appearance, is resistant to UV radiation, is characterized by low dirt retention.

МAssemblage

The STENOFLEX 400 PROTECT ALL cylinders have a special foil strip with an adhesive layer, which works as a hook-and-pile fastener and makes it extremely easy to assemble this material, just by gluing the cut.

| Inner diameter | Wall thickness | |

|---|---|---|

| 10 mm | 13 mm | |

| 12 mm | 13 mm | |

| 15 mm | 13 mm | |

| 15 mm | 20 mm | |

| 15 mm | 25 mm | |

| 15 mm | 30 mm | |

| 18 mm | 13 mm | |

| 18 mm | 20 mm | |

| 18 mm | 25 mm | |

| 18 mm | 30 mm | |

| 22 mm | 13 mm | |

| 22 mm | 20 mm | |

| 22 mm | 25 mm | |

| 22 mm | 30 mm | |

| 25 mm | 13 mm | |

| 25 mm | 20 mm | |

| 25 mm | 25 mm | |

| 25 mm | 30 mm | |

| 28 mm | 13 mm | |

| 28 mm | 20 mm | |

| 28 mm | 25 mm | |

| 28 mm | 30 mm | |

| 30 mm | 13 mm | |

| 30 mm | 20 mm | |

| 30 mm | 25 mm | |

| 30 mm | 30 mm | |

| 35 mm | 13 mm | |

| 35 mm | 20 mm | |

| 35 mm | 25 mm | |

| 35 mm | 30 mm | |

| 42 mm | 13 mm | |

| 42 mm | 20 mm | |

| 42 mm | 25 mm | |

| 42 mm | 30 mm | |

| 45 mm | 13 mm | |

| 45 mm | 20 mm | |

| 45 mm | 25 mm | |

| 45 mm | 30 mm | |

| 48 mm | 13 mm | |

| 48 mm | 20 mm | |

| 48 mm | 25 mm | |

| 48 mm | 30 mm | |

| 54 mm | 13 mm | |

| 54 mm | 20 mm | |

| 54 mm | 25 mm | |

| 54 mm | 30 mm | |

| 57 mm | 13 mm | |

| 57 mm | 20 mm | |

| 57 mm | 25 mm | |

| 57 mm | 30 mm | |

| 60 mm | 13 mm | |

| 60 mm | 20 mm | |

| 60 mm | 25 mm | |

| 60 mm | 30 mm | |

| 64 mm | 13 mm | |

| 64 mm | 20 mm | |

| 64 mm | 25 mm | |

| 64 mm | 30 mm | |

| 70 mm | 13 mm | |

| 70 mm | 20 mm | |

| 70 mm | 25 mm | |

| 70 mm | 30 mm | |

| 76 mm | 13 mm | |

| 76 mm | 20 mm | |

| 76 mm | 25 mm | |

| 89 mm | 13 mm | |

| 89 mm | 20 mm | |

| 110 mm | 13 mm |

| Thermal conductivity, W / m×K | 0.039 |

|---|---|

| Water absorption by volume, no more, % | 1 |

| Operating temperature, | from -60 to +90 |

| Flammability group | G1 |

| Cylinder length, mm | 1000 |

| Reflection of IR radiation, not less than, % | 95 |

| There is no assembling section in | the delivery state |

| The width of the foil strip (fastener) with an adhesive layer, for fixing after assemblage, mm | 15 |

It is suitable for thermal power plants, hydroelectric power plants, nuclear power plants, chemical, oil-producing, and oil-refining enterprises.